Gas plants

Working with industry-leading manufacturers with over 30 years of experience, we provide one of the best full-featured on-site LIN generation packages available. Based on the Gifford-Mahon expansion and cooling technique, the generators have few moving parts, making them some of the most reliable systems available.

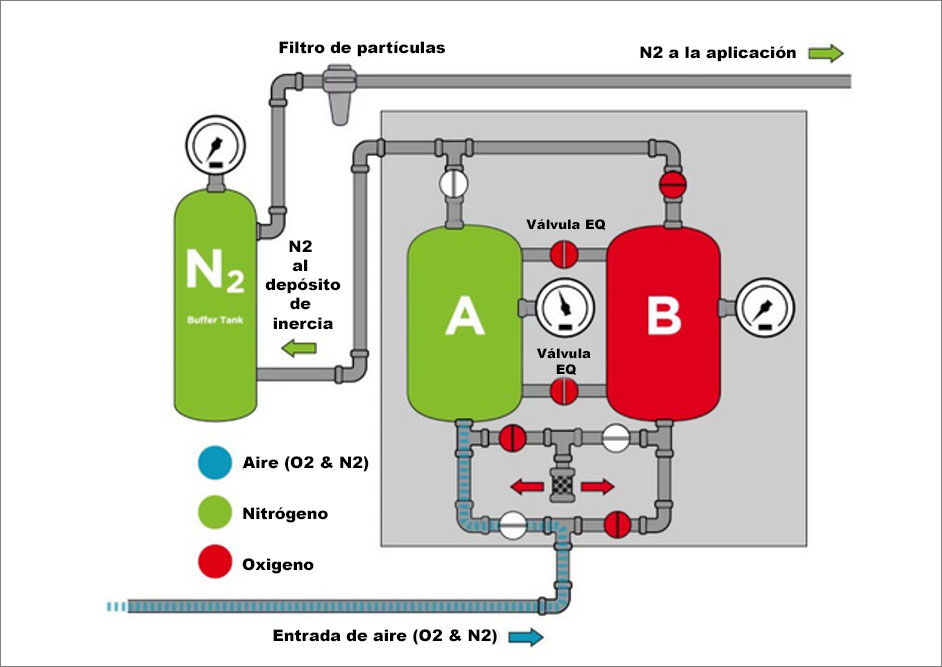

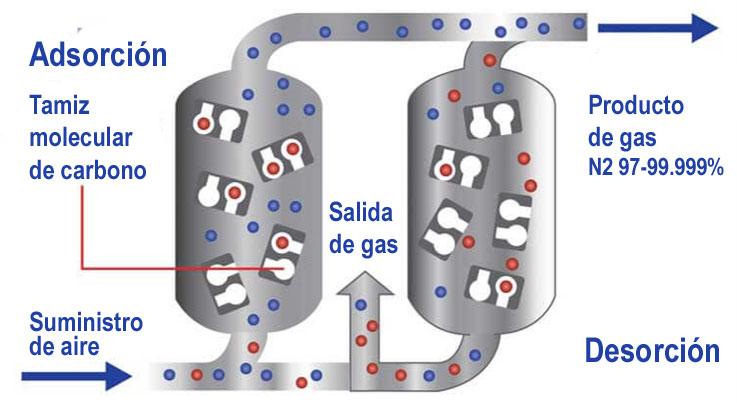

PSA - PROCESS

- Pressure swing adsorption (PSA), a technique used to separate some gaseous species from a mixture of gases (usually air) under pressure, according to the molecular characteristics of the species and its affinity for an adsorbent material.

- Operates at near ambient temperature.

- Selective adsorbent materials (zeolites, activated carbon, etc.) are used as capture material, preferentially adsorbing the target gas species at high pressure.

- The process then switches to low pressure to release the adsorbed gas.

PSA - APPLICATIONS

- Oxygen (medical and non-medical)

- Nitrogen (N2)

- CO2 elimination for large-scale commercial synthesis of hydrogen (H2)

- In the production of ammonia (NH3)

- Separation of CO2 from the biogas to increase the proportion of methane (CH4)

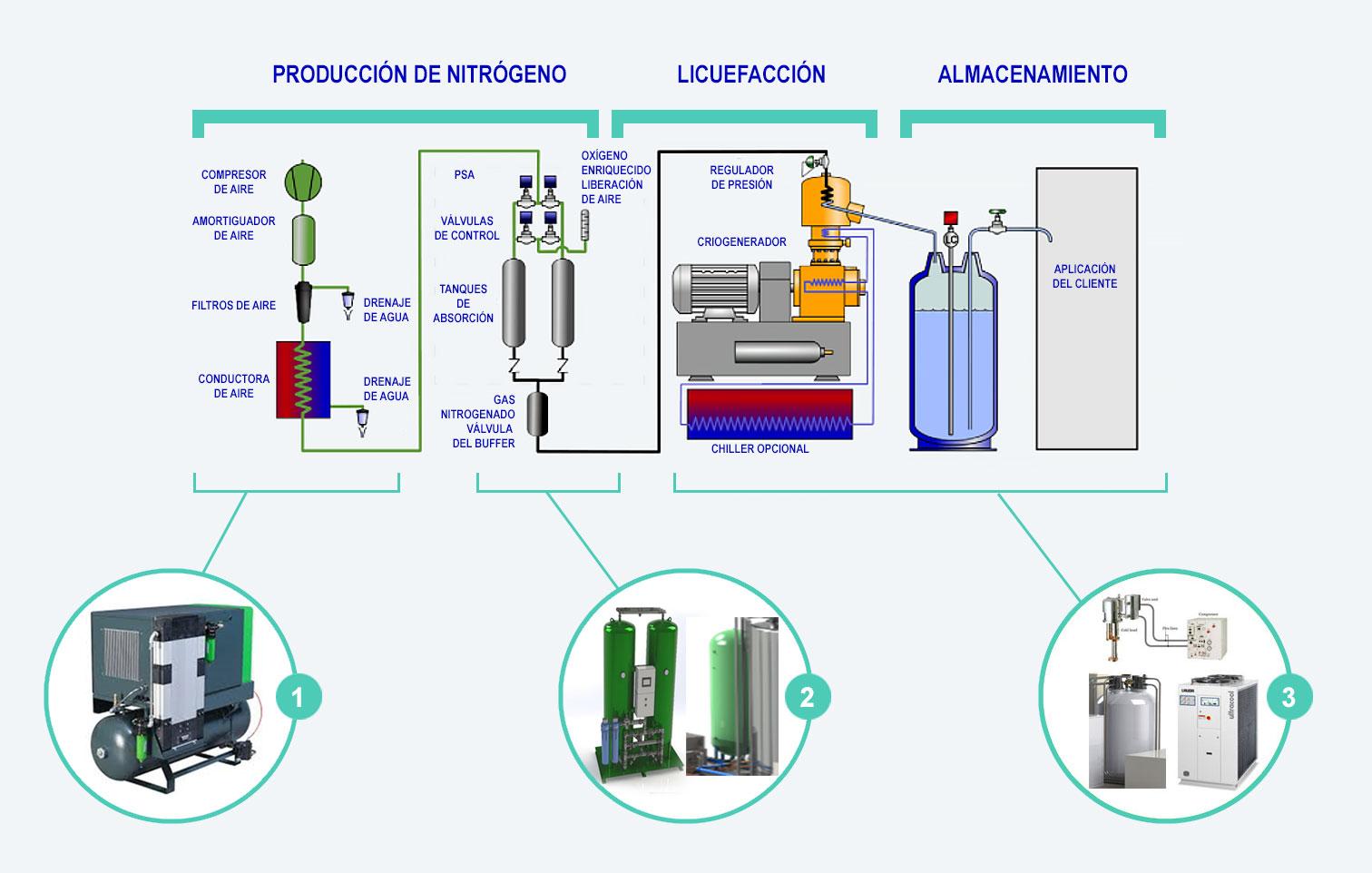

OPERATION OF A LN2 STIRLIN GENERATOR

1. Air compression and pre-treatment

- An AVELAIR compressor is used to compress the humid air (in Cuba the relative humidity is 80%).

- The FF model incorporates the humid air tank, condensate drain valve, air filtering and drying devices, all in one fully assembled unit.

2. N2 generation using PSA

The treated and compressed air feeds a PSA generator that produces N2 and stores it in a 270 liter tank at 11 bar.

3. Liquefaction and storage

- The N2 temperature is decreased to -180°C using a GM cryocooler in the cryogenic tank by means of cold heads located at the top of the tank, fed by Helium compressors.

- A closed-cycle LAUDA Chiller is used to cool the helium in the heads. The N2 liquefaction process occurs in the storage tank itself.

CRYOGENIC COOLING SYSTEM

Cryocoolers GM

- Based on the Gifford-Mahon expansion and cooling technique, GM cryocoolers have few moving parts, making them one of the most reliable systems available for this application.

- They use a different technology than the Stirling engine design and are quieter, have longer service intervals, have more control and use multiple cold heads that are more efficient and cost effective.

- NOBLEGEN has +300 fully operational systems installed worldwide.

Cold heads

- The GM cold head is a system consisting of a closed circuit pre-filled with high purity helium, so no on-site gas service is required (Stirling requires on-site helium service).

- Extremely efficient, quiet and compact system (much bulkier, heavier, inefficient and costly Stirling)

- 30,000 hours maintenance free (Stirling only 4,000 hours)

- LN2 industrial generators have from 1 to 4 cold heads that can work individually to maintain the desired parameters.

- Each head has its own control circuit. The failure of a head does not stop 100% of the production (not so in Stirling).

LAUDA Chillers

- German-made LAUDA Ultracool chiller for cooling helium

- Operates over a temperature range of -10 to 35 °C with stability of ±0.5 K

- IP 54 degree of protection for outdoor use

- Compact and very eco-friendly compared to previous models

- Multifrequency (50/60 Hz). Use of the same model in different geographical latitudes.

- LAUDA is a manufacturer with 65 years of experience in its sector and a global presence.

- SIALEX ring in the water supply to prevent scaling (ERKA Solution)

We provide you with engineering solutions of proven quality with technological equipment of excellent brands, supported by a highly qualified and professional workforce. YOUR BUSINESS PARTNER